Vt Slate Flooring

The Greenstone Slate Company has been a leader in crafting Vermont roofing slate for well over half a century and has shipped slate all over the world for residential and institutional projects. Our quarries are located in the heart of what is known as the Slate Valley— a region primarily in Vermont, extending slightly into New York State.

NEWMONT SLATE COMPANY

- The Shelburne Museum staircase incorporates Honed and Natural Cleft Vermont Mottled Purple Slate. The staircase flows in concert, beautifullyfrom the expansive Natural Cleft Mottled Purple first floor, down through the Bluestone walls, to the solid hardwood floor.

- Vermont Slate Source has one goal - to help friends, both old and new, find the finest roofing slate to fit their needs. And to do so with a competitive price and excellent service. Some of the products we carry include colored roofing slate and cladding, copper nails and slate repair hooks, copper flashings, QWIK Slate and Slate.

Located in Vermont, Newmont Slate Company is the largest roofing slate producer in the United States.

We take great pride in quality service, competitive pricing, fast delivery and superior stone.

QWIK Slate®

Install slate roofing in half the time with QWIK Slate hook strips.

Save money and simplify repairs with the QWIK Slate installation process.

Mansion Slates

Newmont Mansion Slates are undeniably spectacular.

Ranging from 3/4' to 3' thick, these giants produce a classic look reminiscent of the castles of Europe.

The Quarry

Newmont's main quarry in Pawlet Vermont, where great roofs of all shapes colors and sizes are born.

Located in Vermont, Newmont Slate is the largest roofing slate producer in the United States. We take great pride in quality service, competitive pricing, fast delivery, and superior stone.

Newmont Slate Company produces the most and finest Vermont Black Slate in the United States. Newmont President and CEO, John (Jack) Williams has been in the slate quarry business for more than 50 years. With one of the largest and most modern facilities in the slate industry, Newmont Slate Company and it’s numerous quarries in Vermont produce an exceptionally high-quality stone for roofing slate and cladding.

We pride ourselves on our product, hand-split by our highly trained craftsmen. Our attention to detail, quality service, architectural and installation support, competitive pricing, fast delivery, and superior stone are the hallmarks of our business.

Vermont Stone Products

With one of the largest slate inventories in North America, Newmont is proud to offer the richness of color, durability, and natural beauty of genuine Vermont roofing slate and cladding.

Installation Accessories

From stainless steel repair hooks to our patented Copper Clad Drip Edge, we manufacture a wide array of slate repair, installation, and custom engineered accessories.

Patented Install Process

Our patented QWIK Slate and Slate Shield installation processes save time and money while providing the endurance of genuine slate roofing.

The Qwik Slate® roofing installation process will revolutionize the application of slate roofing.

QWIK Slate® improves upon the traditional slate hook method of attachment by pre-applying a series of hooks on a strip. Available in various hook layout patterns to accommodate different slate widths, QWIK Slate® enables super-fast nail gun application and provides superior attachment of Slate to roofing surfaces. All QWIK Slate® hooks are 12 gauge 304 stainless steel anodized black for maximum strength and beauty.

Snow Guards

Slate Roofs—Repair or Replace?

The Language of Slate

The finest lightweight roofing slate installation process available

Newmont’s patented Slate Shield lightweight slate installation process combines traditional slate hook fixing method with advanced water-repelling HDPE panel. Slate Shield saves time and uses half the Slate of traditional installations, reducing weight and cost. Patented wind-resistant “Butterfly” hook makes this process unparalleled in safety and performance.

Installing QWIK Slate® at Our Lady of Good Voyage Chapel in downtown Boston

QWIK Slate® is becoming to go-to installation method for all types of slate projects around the country. QWIK Slate® strips use hooks to support the slates rather than nailing, which allows fast installation and easy maintenance. The strips can be applied with a standard nail gun (stainless steel nails supplied), dramatically increasing productivity.

Simply put, we are proud of our heritage and the products we produce with Nature as our partner.

Contact us today to find out more about our slate products and accessories.

Ideal Carpet for Electronics Manufacturing and

24/7 Critical Environments

Designed to address the most stringent static control requirements

Built to withstand heavy traffic and abuse

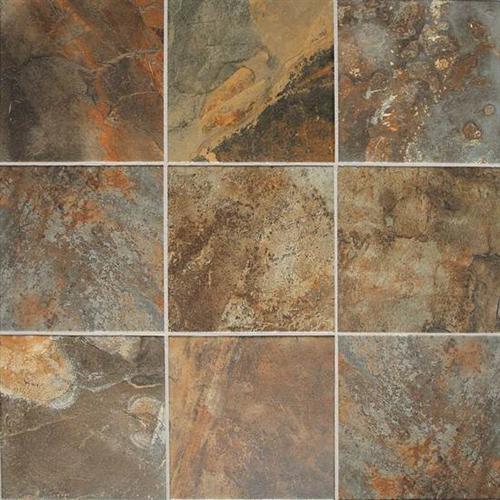

Staticworx Vermont Slate carpet-tile collection provides the durability and high performance you expect from Staticworx floors in a design that transports you to the mountains of Vermont. Warm, monochromatic earth tones promote a peaceful environment, inspiring creativity and a sense of wellbeing and connectedness.

The rock-like etchings in our Vermont Slate carpet tiles flow seamlessly across the surface of the floor in a non-directional or monolithic installation. Merge-ability enables mixing dye lots and saves money by allowing you to add new or replace worn or damaged tiles without worrying about dye lot compatibility.

- Mergeable design - eliminates worry about matching dye lots

- No fade – solution-dyed yarn prevents fading

- Non-directional install method – easy to install and replace

- Durable – rated for high traffic

- Superior static control performance – meets the most stringent ESD standards including ANSI/ESD S20.20 and IEC 61340-5-1:2016*

- Lifetime warranty for static control.

- Static dissipative – meets standards for electronics manufacturing, telecom and government spaces**

Vermont Slate Meets Newest Safety Standards for the Following Environments:

- Electronics handling environments: ANSI/ESD S20.20-2014.

- Resistance: 1 x 106 – 1 x 108: ANSI/ESD S7.1, ANSI/ESD 97.1

- Resistance: 1 x 106 – 1 x 108: ANSI/ESD S7.1, ANSI/ESD 97.1

- Voltage generation < 100 volts: ANSI/ESD 97.2

- Air traffic systems: FAA.STD 019f.

- Equipment rooms, telecommunication areas, and dispatch centers: Motorola R56 Guidelines.

- Network operator equipment areas: ATIS-0600321.2015.

- Healthcare facilities: NFPA 99.

- The controlled electrical properties of Staticworx Vermont Slate collection make it the best choice for electrical safety without compromising performance.

At < 100 volts, Vermont Slate meets the static-protection requirements for charge generation for all Classes of ESD-Sensitive components and assemblies:

| Class | Voltage Range |

|---|---|

| Class 0 | < 250 volts |

| Class 1A | 250 volts to < 500 volts |

| Class 1B | 500 volts to <1,000 volts |

| Class 1C | 1,000 volts to <2,000 volts |

| Class 2 | 2,000 volts to <4,000 volts |

| Class 3A | 4,000 volts to <8,000 volts |

| Class 3B | ≥ 8,000 volts |

ESDS Component Sensitivity Classification for the Human Body Model (Per ESD-STM5.1)

Cost Effective

- Non-directional design eliminates the hassle of matching patterns and dye batches, and hides wear and tear—the main cause of carpet tile replacement. This results in significant savings.

- Installed with releasable adhesives. Releasable adhesives allow for easy removal of individual tiles, as opposed to having to remove entire rolls of broadloom carpet. This significantly reduces installation waste.

- Glue-free option, using TacTiles, means carpet can be installed without disrupting critical 24/7 operations.

Convenient

- Can be installed non-directionally, making it ideal for raised access floors.

- Mergeable dye lots allow you to replace tiles from future batches without concern for matching the original installation.

- Slight variations are listed under Additional Specifications

Visually Appealing

- Unique design patterns use biomimicry to simulate the random beauty of nature.

- Promotes calming effect

- Non-directional design and mergeable dye lots allow easy tile replacement and mask wear, providing long-lasting aesthetic appeal.

Sustainable, Durable, Reliable

Vermont Slate Tile Flooring

- Contains almost 50% recycled content and has low-emitting material.

- May qualify for LEED (Leadership in Energy and Environmental Design) credits.

- 100% of yarn bundles are wrapped with Helix 44 denier static-control fiber.

- Withstands over 100,000 cycles of Phillips roller caster chair test.

- Fibers rated at < 2.0 Modification Ratio

- Why is this important? See This Article

- Lifetime warranty for static control.

- Made in America.

ShadowFX™ SDC - Vermont Slate Collection Colors

Actual tile size is 50cm x 50cm.

Actual tile size is 50cm x 50cm.

Actual tile size is 50cm x 50cm.

Actual tile size is 50cm x 50cm.

Actual tile size is 50cm x 50cm.

Actual tile size is 50cm x 50cm.

Actual tile size is 50cm x 50cm.

Actual tile size is 50cm x 50cm.

Actual tile size is 50cm x 50cm.

Actual tile size is 50cm x 50cm.

Actual tile size is 50cm x 50cm.

Actual tile size is 50cm x 50cm.

How to Qualify and Specify an ESD Floor

What is your application? If you're qualifying a floor, it matters. ESD flooring should always be qualified and specified based on ANSI/ASTM, ATIS, or other industry-specific standards.

Universal standards - based on application and environmental conditions - vary by industry. For electronics manufacturing and handling applications, where special ESD footwear is required, specifications should be based on ANSI/ESD S20.20-2014.

Specifications should reference test methods ANSI/ESD STM 7.1 and STM 97.2.

Standards for ESD flooring materials for electronics manufacturing and handling:

- Resistance, measured in ohms, per STM 7.1:

- < 1.0 x 109 ohms

- Charge generation, measured in volts, per STM 97.2:

- < 100 volts at peak

Floors for end-user spaces where electrified (operational) equipment is in use, refer to standards specific to the industry – e.g. Motorola R56, ATIS-0600321.2015, for telecom and dispatcher spaces, FAA 019f for FAA flight towers, Army Corps of Engineers, Spec #: UFGS 09 62 38, for construction of military services, etc.

Standards for most end-user spaces:

- Resistance, measured in ohms, per STM 7.1:

- 1.0 X 106 to 1.0 X 109

Slate Flooring Pros And Cons

- Charge generation, measured in volts, per STM 97.2:

- < 500 volts (.5 kV)

Installation Methods

Monolithic

Downloads

Specifications

General Specifications

| Product Construction | Tufted Textured Loop | |

| Yarn System | Post-Consumer Content Type 6,6 Nylon | |

| Yarn Manufacturer | Universal | |

| Dye Method | 100% Solution Dyed | |

| Dye Lots | Mergeable | |

| Soil/Stain Protection | Protekt²® | |

| Preservative Protection | Intersept® | |

| Imperial | Metric | |

|---|---|---|

| Tufted Yarn Weight | 17 oz/yd² | 576 g/m² |

| Machine Gauge | 1/12 in | 47.2 ends/10cm |

| Pile Height | 0.13 in | 3.3 mm |

| Pile Thickness | 0.071 in | 1.8 mm |

| Stitches | 9 /in | 35.4 ends/10cm |

| Pile Density | 8,620 oz/yd³ | 319,627.7 g/m³ |

| Size | 19.69 in x 19.69 in | 50cm x 50cm |

Performance Specifications

| Flooring Radiant Panel | (ASTM E-648) Passes | |

| Smoke Density | (ASTM E 662) ≤ 450 | |

| Flammability | Passes Methenamine Pill Test (DOC-FF1-70) | |

| Lightfastness | (AATCC 16 - E) ≥ 4.0 @ 60 AFU's | |

| Static | (AATCC - 134) < 3.0 KV | |

| Dimensional Stability | AACHEN Din 54318 <.10% | |

| Traffic Classification | Heavy | |

| Fiber Modification Ratio | 1.7 to 1.9 | |

| Preservative Efficacy | (AATCC 174 Parts 2&3) 99% Reduction/No Mold 7 Days (ASTM E-2471) Complete Inhibition | |

Environmental Specifications

| Total Recycled Content | 63% | |

| Recycled Content (Post Industrial) | 61% | |

| Recycled Content (Post Consumer) | 2% | |

| Indoor Air Quality | Green Label Plus #GLP0820 | |

| Ingredients and Life Cycle Impacts | Environmental Product Declaration | |

| Other Environmental Claims | 3rd Party Verified Carbon Neutral NSF/ANSI 140 Gold - Sustainability Assessment | |

| End of Life | Carpet to Carpet Recycling | |

Electrical Resistance

| Conductive Fiber | Staticworx Helix 44 Denier Conductive Fiber | |

| kV Rating | AATCC 134-1996 electrostatic propensity: less than 0.4 kV (400 volts). Tested at 12% relative humidity at 20°C and 70° F | |

| Body Voltage Generation (BVG) Per ANSI/ESD S97.2 | Voltage on person in combination wwith grounded carpet tile <50 volts. Meets ANSI/ESD S20.20-2014 requirements for use in EPAs in electronics manufacturing. | |

| ESD S7.1/NFPA 99 Resistance Characterization of Materials | Nine or more readings from surface to groundable point. Tested with an applied voltage of 100V. Measured in OHMs, 1.0 x 106 – 1.0 x 108 | |

| ESD S7.1/NFPA 99 Resistive Characterization of Materials | Nine or more readings between electrodes placed 1 foot apart. Tested with an applied voltage of 100V. Measured in OHMs, 1.0 x 106 – 1.0 x 108 Meets Motorola R56 and ATIS-0600321 for use in telecommunications applications. Meets FAA STD 0196 for use in flight control applications. Approved for EPAs per ANSI/ESD S20.20

| |

| Electrical Resistance/Voltage Test ANSI/ESD S-20.20 | Approved for use in EPAs in electronic manufacturing with approved footwear system. Results within recommended range < 35 x 106 OHM or < 100 volts. | |

| D.O.D. HDBK263A, Section 40.1.2 | Meets recommended guidelines for sensitive ESD devices. Class 1. | |

| Roller Caster Electrical Test (CET) proven | Product meets ANSI/ESD S20.20 after 125,000 cycles. | |

| Groundable Path | Copper ground strip. | |

| Grounding Frequency | 1 per 1,000 sq. ft. | |

| Backing Systems | Permanent static-dissipative backing. | |

| Adhesives | Use only Staticworx-approved conductive adhesives. GroundTack pressure sensitive. GroundWise corner pads for adhesive-free instalations over raised access floors. | |

Want to go glueless?

All styles can be installed with GroundTack® adhesive or Go Glue-less using TacTiles® and GroundBridge™